- #Solidwork 2010 crack how to

- #Solidwork 2010 crack full version

- #Solidwork 2010 crack software

- #Solidwork 2010 crack professional

- #Solidwork 2010 crack series

#Solidwork 2010 crack software

This software program is helpful for architectures, designers, and engineers alike.

#Solidwork 2010 crack professional

There are advanced and powerful features for professional designing. Computer Repair Shop Software Free Download more.

#Solidwork 2010 crack full version

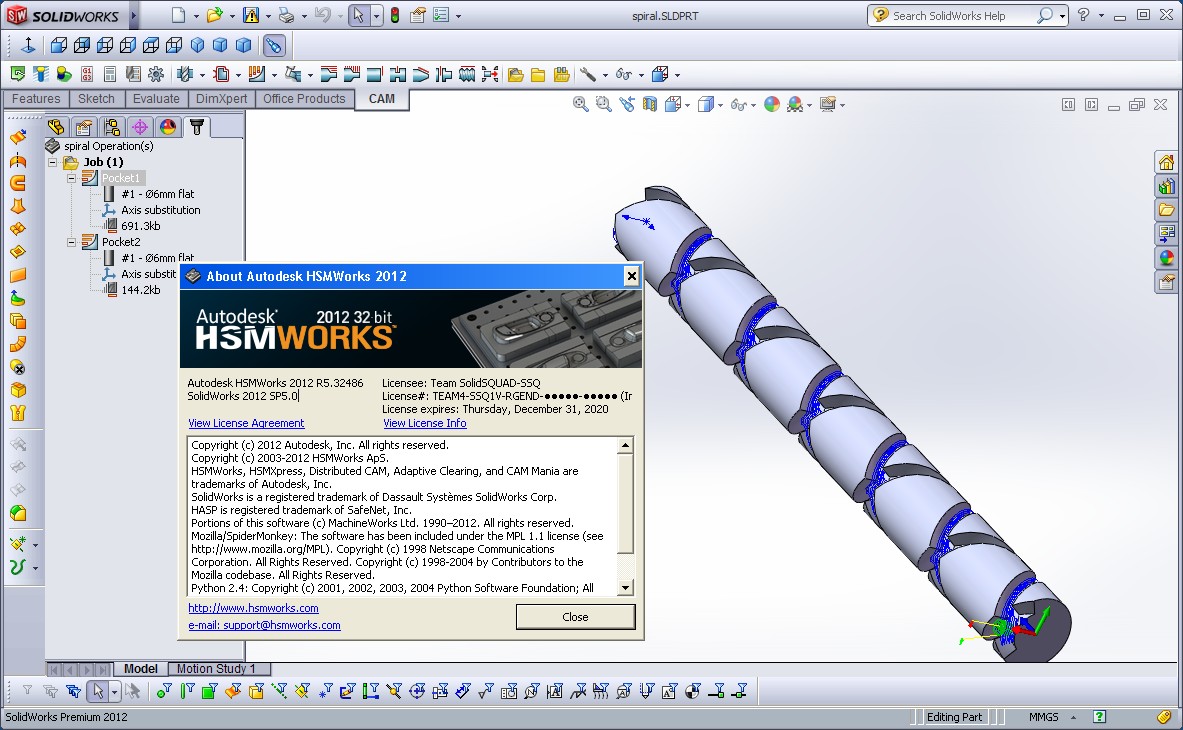

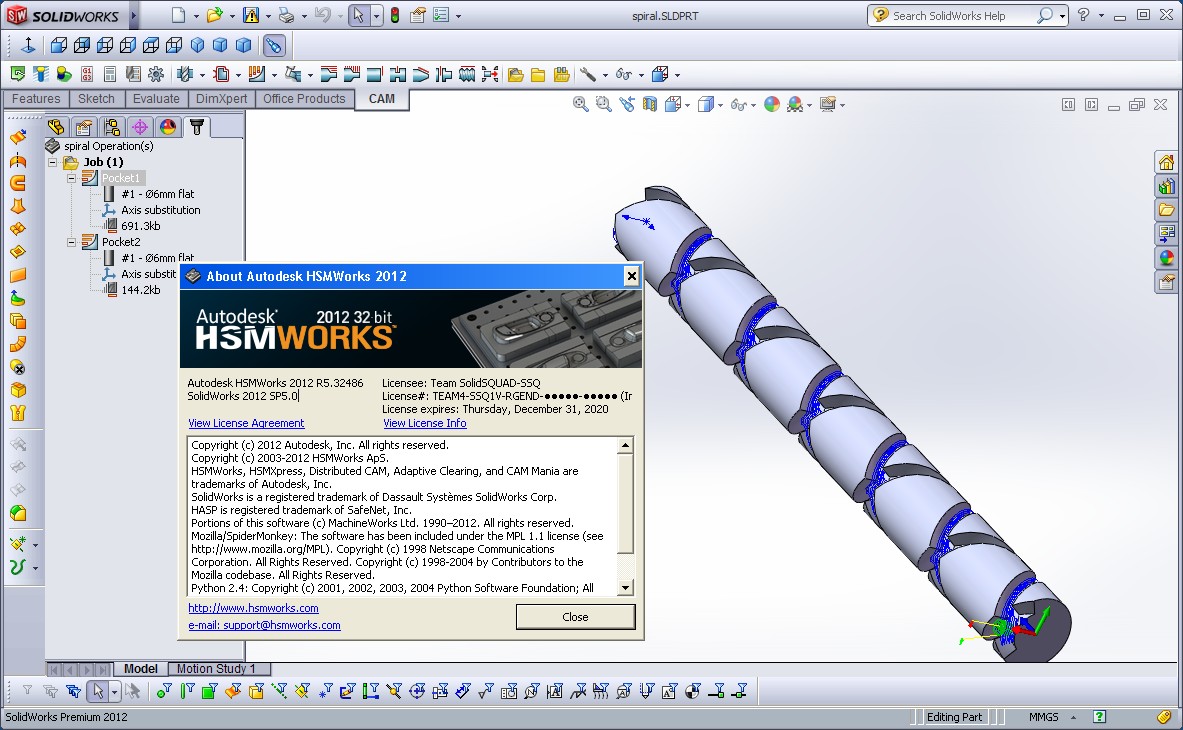

Solidworks Free Download Full Version enhanced all the qualities that should be given in every quality software. SolidWorks Free download is a comprehensive software application ever. It is very flexible because it reduces the time required to build complex 3D models. It is the competent and integrated model solution. Solidworks Free Download Full Version SolidWorks free download with crack fully based on leading visualCAm software application. The latest version of the program can be downloaded for PCs running Windows XP/Vista/7/8/10, 32-bit. SolidWorks 2010 SP0.0 32 & 64bit Full hotfile download share. Recorded using Version 1.3.Solidworks,full SolidWorks 2010 SP0.0 32. In Part I, you will see how boundaries are used to retain edges for both materials and SolidWorks features.

#Solidwork 2010 crack series

This two-part series takes the mystery out of the Boundary tool by showing how, when and why it is used. Click Isometric from lower left view menu. To engrave the text, click Features, click Extruded Cut, under Direction 1 Blind, set D1 to 0.01in and. Click to part face to relocate text to center. One piece of software that does that easily is AutoCAD.

Converting SolidWorks to LaserCutting: Since SolidWorks can’t save a file in a format that a laser cutter understands, we need a bit of software in between SolidWorks and the laser cutter to do that file manipulation for us. It does however allow you to set a pull direction which can come in handy on plastic parts. The only disadvantage of it versus the Extrude is the lack of a built in Draft Option. You can also Emboss or Deboss (cut) solids with this tool. Step 2: To … Continue reading "Radius and Diameter Dimensions (switching these in SW 2009)" Choose Display Options>Display as a Diameter. Step 1: To change a radius to a diameter, RMB click on the radius dimension. One can become another quickly in SolidWorks 2009. It doesn’t matter if the dimension starts off as a radius, diameter, or a linear diameter dimension (on a drawing in a model). Go to feature command manager and select extrude boss/base feature button. Then “ exit the sketch ” and select the “ sketch-1 ”. Using Smart dimension tool, apply the given length ( 100 mm) and breadth ( 60 mm ). Then draw a rectangle in the graphics area. Go to sketch and select rectangle button from command manager. Converting SolidWorks to LaserCutting: Since SolidWorks can't save a file in a format that a laser cutter understands, we need a bit of software in between SolidWorks and the laser cutter to do that file manipulation for us. #Solidwork 2010 crack how to

(1) How to use Mouse Gesture in Solidworks 2010 (1) InspectionXpert for SolidWorks 2011 (1) InspectionXpert for SolidWorks 2011-2 (1) Layout in SolidWorks (1) Mate Enclosure - Part 1 (1) Mate of Enclosure - Part 2 (1) Mold and Cavity (1) Multi Draft Cuts with Adv Surfacing (1) o Draw Hexagonal by Swept Boss (1) Outline Sketches in Solidworks.

This SolidWorks Tutorial shows how to use surface to cut the solid part. I usually extrude cut thru the center of the part to remove the other half in SW, make a STL file, then move the cutting tool in SW to the other side and remove that material and make a STL file.

I take a cut line in the part that would make it easy to put it together it does not have to be in the center, what works best for your print. Solidworks Cut List Customization Mp3 Download. Solidworks veri oluşturmanızı, analiz etmeniz, yayınlamanızı ve yönetmenizi sağlayan eksiksiz 3 boyutlu katı modelleme yazılımıdır. While modeling a multi-body part file in SOLIDWORKS 2019, the standard Cut-List Properties are enough to get most jobs done and out to manufacturing. Under resulting bodies, enter the file names for the two bodies. Select the plane or sketch to be the trim tool. Here is probably the most SolidWorxy: Create a plane through the middle of your part, or draw a sketch that is a line that shows where you want to split the. Once you start making a structure using Weldment functionality, SOLIDWORKS generates a list of the components in the Weldment part which is called a Cutlist. A Weldment structure is a unit formed by welding an assembly of parts together.  SOLIDWORKS Weldment functionality is a great tool to make a weldment structure.

SOLIDWORKS Weldment functionality is a great tool to make a weldment structure.

However, if the part was made with Sheet Metal features, the manufacturing information was not transferred to the mirrored part.

SOLIDWORKS has always had a great part mirroring function that accomplished this in no time, eliminating the need to completely create the new part from scratch.

0 kommentar(er)

0 kommentar(er)